BlueCoil Technology

The next generation of coiled tubing

BlueCoil™ technology is a new, industry changing technology designed to expand the capabilities of coiled tubing and raise the operational quality and performance to the next level. It is also a technology platform for extending coiled tubing capabilities and reliability to meet future extreme operational demands. BlueCoil™ technology is based on new steel designs and new manufacturing processes to produce coiled tubing that is stronger and more fatigue and environmentally resistant throughout its structure.

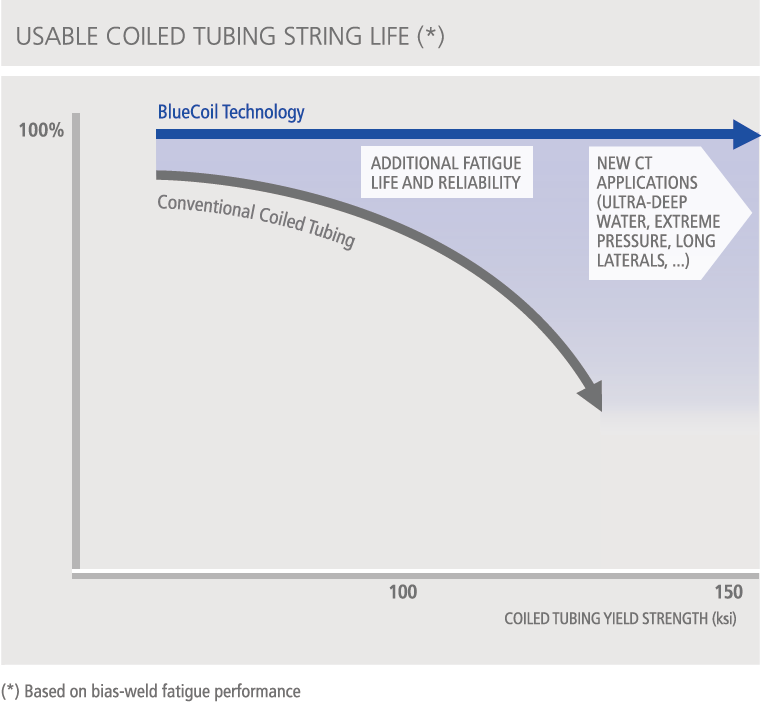

The life of a conventional coiled tubing string is normally limited by the fatigue life of its bias welds. As the required yield strength of coiled tubing increases, the fatigue life of the conventional bias weld decreases relative to the rest of the coiled tubing string, limiting the useful life of the entire string to the shorter life of the bias weld.

In contrast, the bias weld and base tube fatigue performance of a BlueCoil™ string remain comparable for high strength coiled tubing grades, allowing greater utilization of the entire string, bringing additional strength, reliability and longer string life for coiled tubing applications.

BlueCoil™ technology is backed by Tenariss decades of experience and research in pipe manufacturing and metallurgy. BlueCoil™ products have undergone comprehensive testing to validate their advanced metallurgical, mechanical, fatigue and environmental performance. Field experience has confirmed quantifiable benefits of BlueCoil™ products in real-life operations.

An innovative manufacturing process

To create BlueCoil™ technology Tenaris developed new steel chemistries and new welding and heat-treatment processes that are exclusive for coiled tubing (patents pending.) They were designed to obtain higher strength grades and provide significant improvements infatigue performance and sulfide stress cracking (SSC) resistance.

Most of the conventional coiled tubing properties are obtained when the flat strips are manufactured at the steel mill. The optimized microstructure and properties of the original flat strip material are later degraded in the bias and seam weld areas.

On the contrary, the final properties of a BlueCoil™ string are obtained at the last stage of the manufacturing process. As a result, there is an improved microstructure and more uniform material properties across the entire string, including the bias and seam welds.

Great ly Improved general and sour fatigue Performance

BlueCoil™ technology brings improved fatigue performance over conventional coiled tubing grades. This benefit extends to the bias welds, as they have the same improved microstructure as the base tube. In conventional coiled tubing, the shorter fatigue life of the bias weld limits the useful life of the entire string. With BlueCoil™ technology, the fatigue life of the bias weld is similar to that of the base tube.

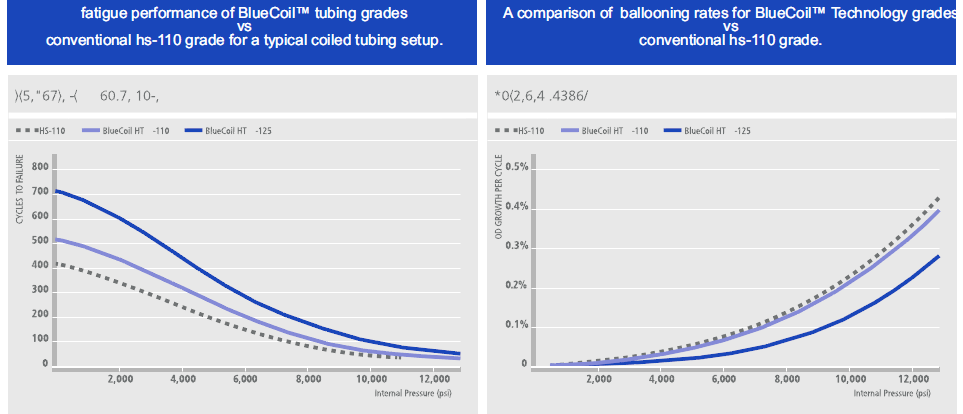

BlueCoil™ products resist ballooning better than conventional coiled tubing, making them ideal for high-pressure applications.

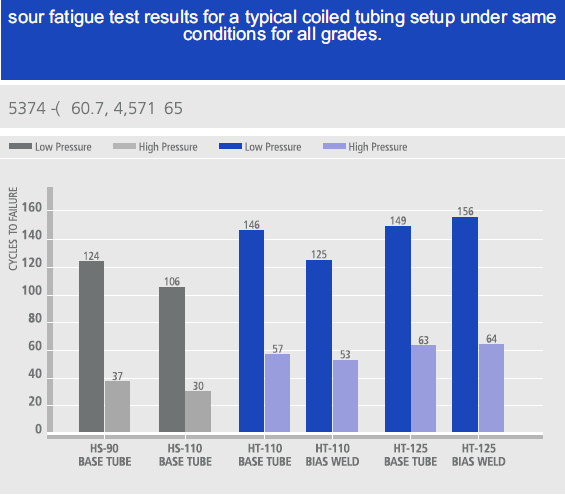

Extensive testing shows that fatigue performance of BlueCoil™ products after sour (aqueous H2S) exposure is markedly improved when compared to conventional coiled tubing grades. Additionally, fatigue life of conventional coiled tubing grades after sour exposure decreases as the coiled tubings yield strength increases. BlueCoil™ technology enables a more effective and more reliable usage of higher yield strength grades, as the sour fatigue life of BlueCoil™ grades did not show to be adversely affected by yield strength increases.

With BlueCoil™ technology, the performance of the bias weld in sour fatigue is very similar to the performance of the base tube. The improved and homogeneous microstructure of BlueCoil™ products results in significant sour fatigue improvements for both the base tube and bias welds. In conventional coiled tubing, bias welds typically fail in sour fatigue much sooner than the base tube, even for the lower-strength grades.

Significantly Better Sulfide Stress Cracking (SSC) Resistance

BlueCoil™ technology shows improved SSC performance, allowing the use of 20 ksi to 30 ksi higher yield strength grades in SSC environments compared to conventional coiled tubing grades.

Hydrogen induced cracking (HIC) tests show that all the coiled tubing grades, including conventional and BlueCoil™ technology, have good HIC resistance.

Easy to handle

BlueCoil™ products are compatible with the equipment currently used with conventional coiled tubing, so there is no need for special handling or equipment requirements.

This includes injector handling under high pull load, BHA connectors and BOP shear and slip performance.

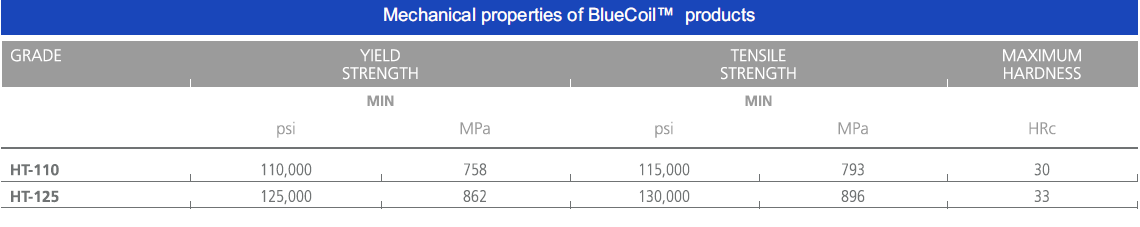

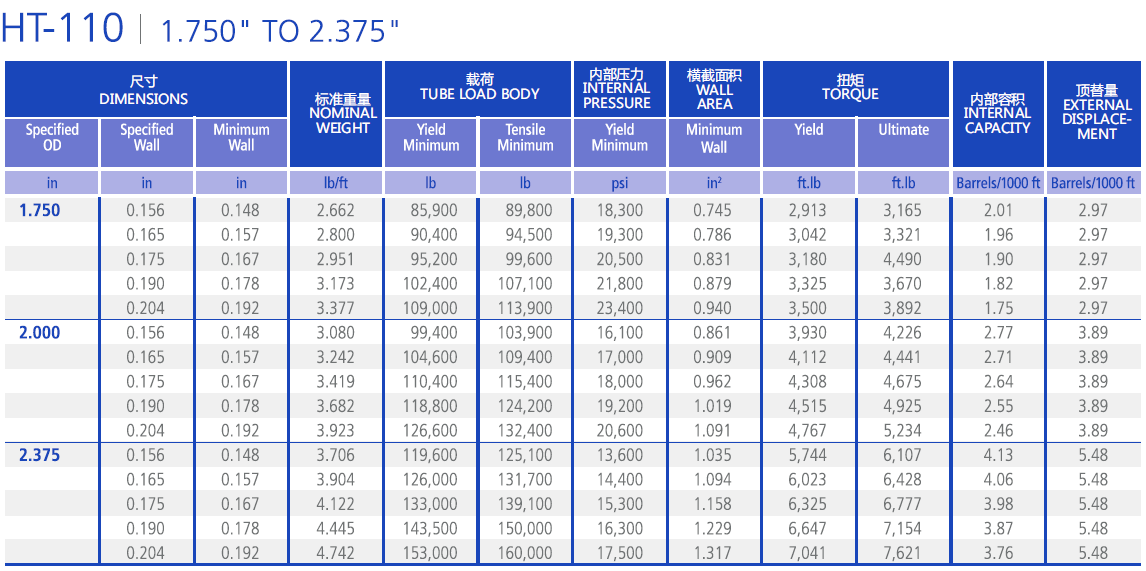

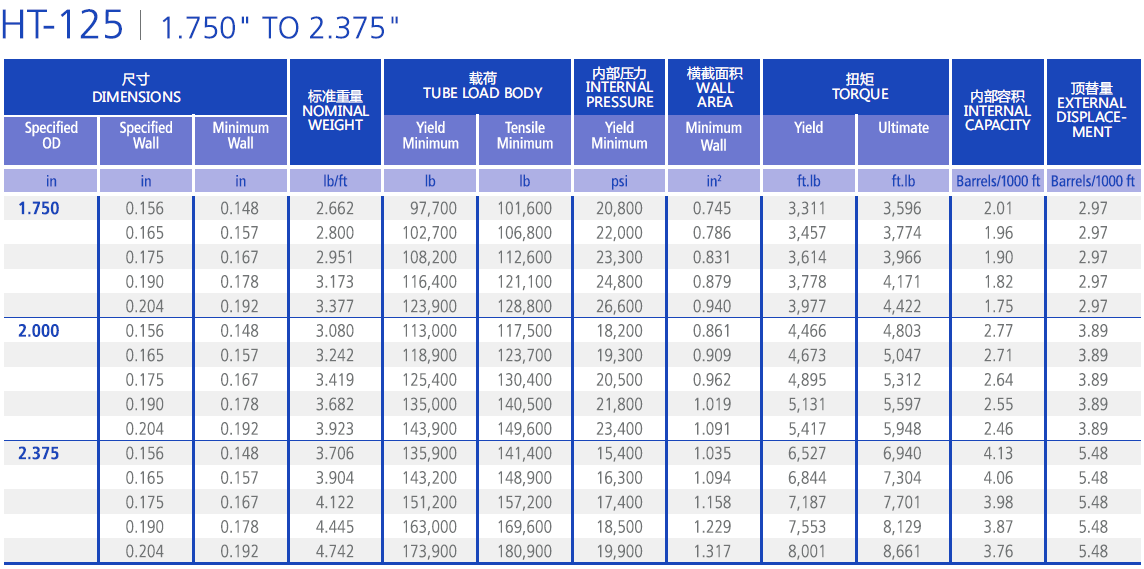

Mechanical properties

Technical Tables

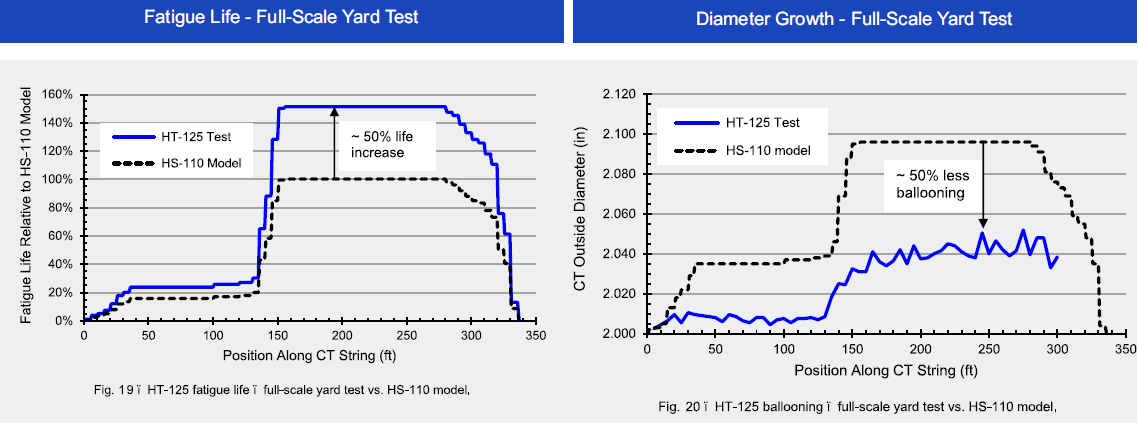

Full-Scale Yard and Field Performance

Conclusions

New coiled tubing (CT) technology and manufacturing processes were developed using new steel chemistries, manufacturing and heat-treatment processes. The resulting tempered martensite microstructure is obtained uniformly along the entire CT string, including bias and seam welds. This provides significant improvements over the conventional CT in which less favorable microstructures of ferrite, pearlite and bainite are attained and subsequently degraded in the bias-weld and seam-weld areas.

Coiled tubing made using the new technology showed significant performance improvements in sour (wet H2S) environments under static load conditions, i.e., better resistance to sulfide stress cracking (SSC) resulting from the improved material microstructure. The results imply that the improved SSC performance of the new CT grades could allow the use of a 20 ksi to 30 ksi higher-yield-strength grades in SSC environments compared to the conventional CT grades. Hydrogen induced cracking (HIC) tests showed that all CT grades have good HIC resistance for the sour conditions covered by the tests.

The new HT-110 grade has on average about 30% longer fatigue life than the conventional HS-110 grade across the whole range of internal pressures. The HT-125 grade showed about 90% improved average fatigue life compared to HS-110.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......