Traceless Soluble drilling-free large-diameter bridge plug

Product features

Soluble-based alloy is adopted as the raw material of traceless soluble drilling-free large-diameter bridge plug, which dissolves automatically without residual in underground water-bearing media environment after fracturing, thus meeting the technological requirements of no drilling and milling. Presently, such soluble bright plug is produced and sold by batches in Houston.

Superiority

• Instant solution. It can clear large-diameter channel automatically after 7 days together with quick soluble ball. Normal operation can be ensured even if bridge plug is not dissolved completely;

• Quick drilling. Bridge plug can be drilled in 15 min even in case of blocking;

• Large diameter. Outer diameter series ø105, ø108.9, ø111, etc. / inner diameter series ø56, ø58, ø60, etc;

• High strength and good stability. Tensile strength of soluble al-based alloy can reach 620 MPa, pressure-bearing indicator of bridge plug is 80 MPa, and temperature resistance is as high as 150°C.

Features

• Fit for various bushings

• Capable of dissolving completely in 1 month after seat seal fracturing

• Large inner drift diameter

• Resistance to high temperature

• High strength

Parameters

• Outer diameter: ø105, ø108.9, ø111 mm

• Inner diameter:ø56, ø58, ø60 mm

• Seat seal force: 140 KN (±10%)

• Temperature resistance: 150°C

• Strength: 80 Mpa

Materials

• Slip element: nano whisker zirconia

ceramics

• Packer rubber: modified cyaniding NBR

• Base: soluble al-based alloy base material

Dissolution principle

Dissolution mechanism of soluble metals

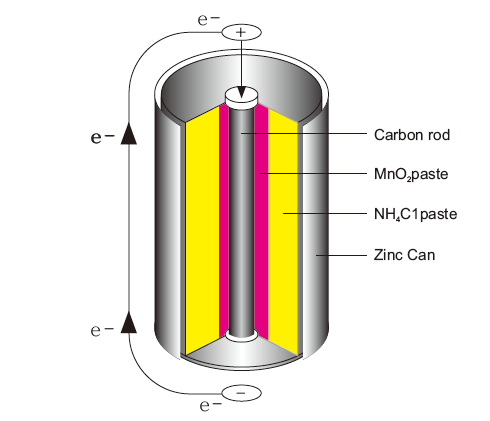

1. Electrochemistry theory

Take al-alloy as the base material and add elements such as Mg,Sn, C and Zn to prepare soluble material by followingelectrochemistry theory. Such material feature is slow dissolution rate.

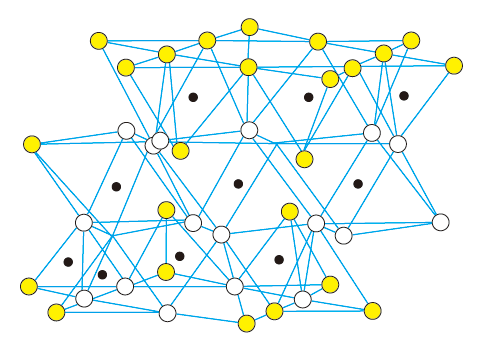

2. Oxide film breakup theory

Add rare earth element into al-alloy material to prevent it forming dense oxide film and relieve it from protection of oxide film, thus making metal material soluble. The rate of destroying oxide film of al-alloy can be controlled by changing the content of rare earth element, to finally control the dissolution rate of metal materials.

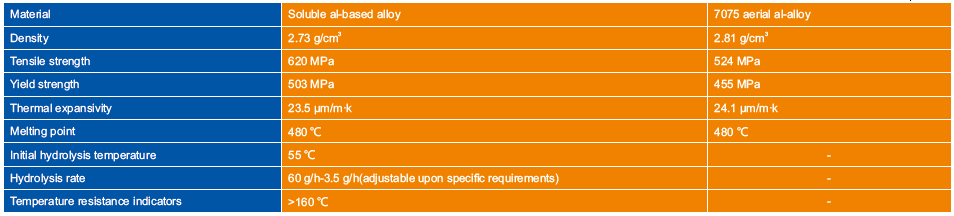

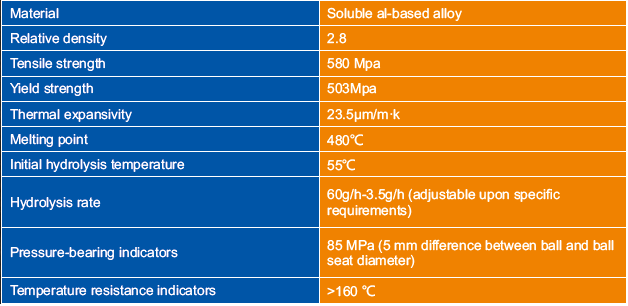

Material characteristics

Mechanical property and parameters of soluble al-based alloy(compared with 7075 aerial al-alloy)

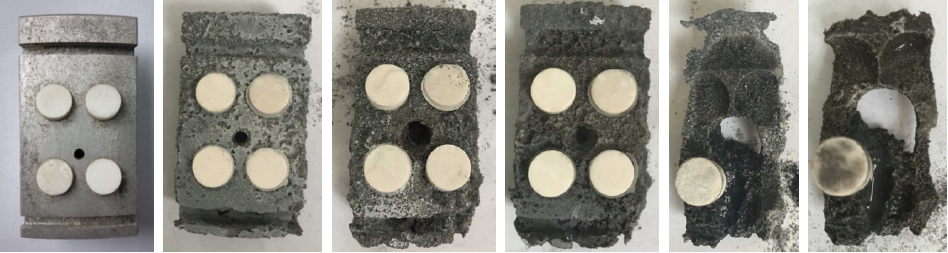

Dissolution experiment

Soluble slip of soluble metal bridge plug has passed indoor bearing testing, with pressure resistance of greater than 80 MPa and temperature resistance of greater than 150°C. And indoor dissolution test is conducted to obtain dissolving time of less than 120 h for single slip.

Comparison chart for dissolution experiment of soluble slip

After slip dissolution experiment is carried out in University of Houston, the dissolution shapes of slip in simulated petroleum downhole solution medium in different time periods are shown below:

Soluble metal fracturing ball

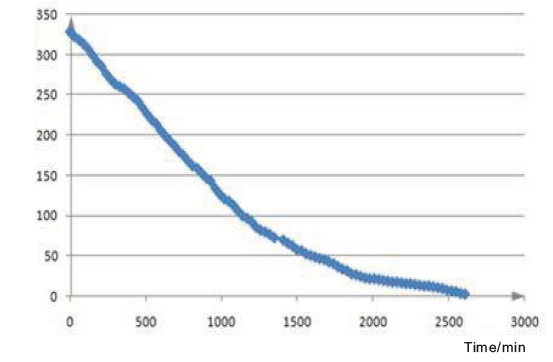

Comparison chart for dissolution experiment of soluble fracturing ball

Through dissolution experiment on fracturing ball by Institute of Metal Research, Chinese Academy of Sciences, the dissolution shapes of

soluble fracturing ball in simulated petroleum downhole solution medium in different time periods are shown below:

• Dissolving medium: P>80 MPa in simulated petroleum downhole medium;

• Dissolving temperature: T> 150°C in simulated petroleum downhole medium;

• Dissolving time: t<120 h for single fracturing ball.

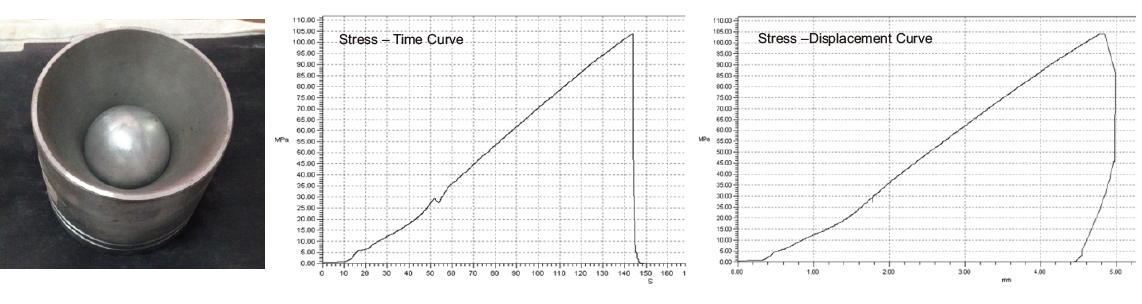

Compressive test

Diameter of the ball used is tested to be 60 mm, ball seat diameter is 56 mm and temperature is 160°C oil immersed. Testing pressure of 103 MPa is adopted to stabilize the pressure for 20 min.

In simulated petroleum downhole solution medium, dissolution rate of soluble fracturing ball in different time periods is shown below:

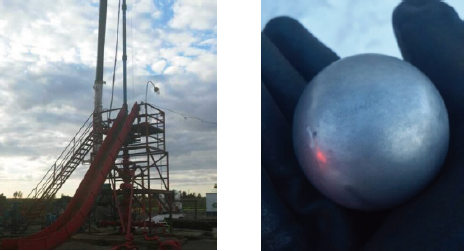

Domestic field application

Operating site:No. 9 Oil Recovery Plant of Daqing Oilfield

Operation effect:On July, 2015, Daqing Oilfield in Heilongjiang carried out combined construction of pumping cable perforation and soluble bridge plug.Fracturing construction of 6 segments of 5 bridge plugs was finished after three days. Soluble bridge plug was adopted for Level 1 and Level 5, while large drift diameter quick-drilling bridge plug was used for the three immediate levels.The effect is good.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......