Technique Service of Solid-free Combined Brine Drilling Fluid System

Introduction

Bntonite plays an essential role in traditional polymer and plymer slfonate drilling fluid as a kin of indispensable treating agent.

However, research shows thatparticles of bentonite with full hydration and high dispersion affacts the drilling rate greatly far

more than the effect of cuttings and weighting materials. Brine has a high salinity, which makes brine drilling fluid inhibitiveand

able to suppress hyration and swelling of shale, keep borehole stability and prevent borehole collapsing. The brine system is

solid-free and takes xanthan gum as tackifier. The salt is not only the inhibitor but also the weighting agent, and only a samll

amount of sluggish eighting material is enough to increase the drilling fluid density to the required value, which decreases the

solid content in drilling fluid and improves the drilling rate significantly. Solid-free sodium chloride and sodium formate combined brine si our new drilling fluid system recommended in recent years and has been applied widely in drilling engineering of many oil fields.

Advantages

• Good ability to suppresshydration and swelling of shale, keep borehole regular and stable, and prevent borehole collapsing;

• With extremly low solid content and significantly improving drilling rate;

• High debris recovery, good debris shaping, easy to clean the solid control equipmentand low poor solid content in drilling

fluid;

• Good ability to suppress formation mud making, easy to control the rheological property and with stable performance;

• Making finely mud cake and with good lubricity effectively mitigating the backing pressure of the drilling tools in slide drilling;

• Easy to prepare and maintain and low cost.

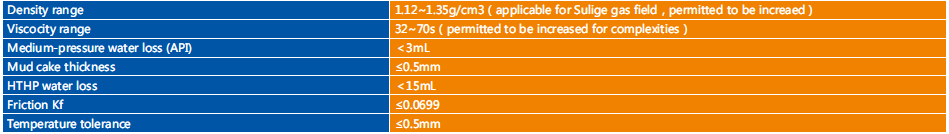

Technical Indicators

Application Cases

Our technique is mature and has been applied in nearly 90 vertical, directional and horizontal wells in oil or gas fields such as

Qinghai oil field, Changqing oil field, Yanchang oil field and Sulige gas field. Thereinto the biggest drilling fluid density in Well Xian X and Xian X reaches 1.95 g/cm3 with stable drilling fluid propertyand supressing the pollution of several high-pressure saline layers. Our technique has been used for more than 50 wells easy to collapse and leak and horizontal wells(with the biggest length of horizontal segment of 1800m) in Changqing oil

field.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......