Tracking and Evaluation of Production Capacity with Indicator

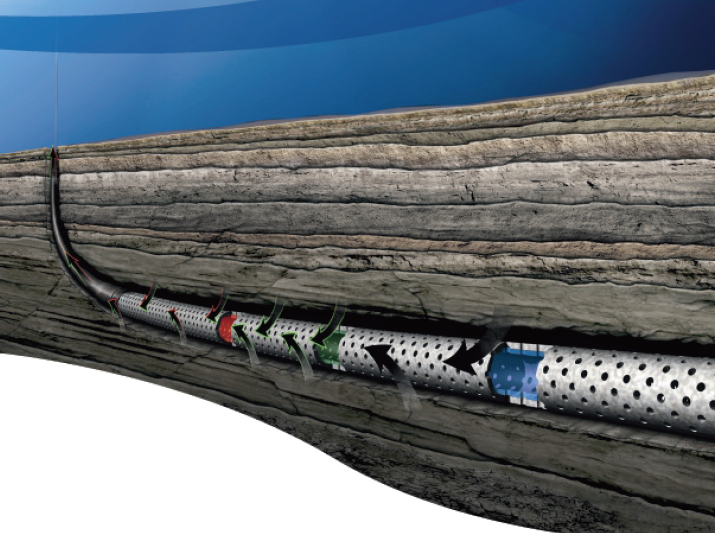

Principle

During separate-layer or staged fracturing, add different volume and kinds of indicators (inexistent in original formation, with high stability, nonreactive with formation rock and fluid, and with good temperature and pressure tolerance) based on different reservoirs

and inject it with the operating fluid into the reservoir.And information such as liquid production capacity and flowback rate of each section can be calculated from the output concentration of all indicators by the analysis of sample test obtained through continuous sampling during flowback process. Such indicator is mainly used to evaluate the production capacity, contribution rate and flowback rate of each section and also the fracturing effect

providing the basis for wells to be fractured in future. Issues like whether sand bridge occurs during flowback can be determined by use of indicator.

Advantages

• Nonhazardous, nonradiative, non-pollution and no damage to the formation, safe and environmental;

• No effect on fracturing fluidproperty;

• Nonreactive, no precipitate forming or isotope exchanging with formation fluid;

• Good temperature tolerance and chemical stability, acidandacid-resisting, and low formation absorption;

• No disturbance between different kinds of indicator, easy to identify and distinguish, and with high detection sensitivity.

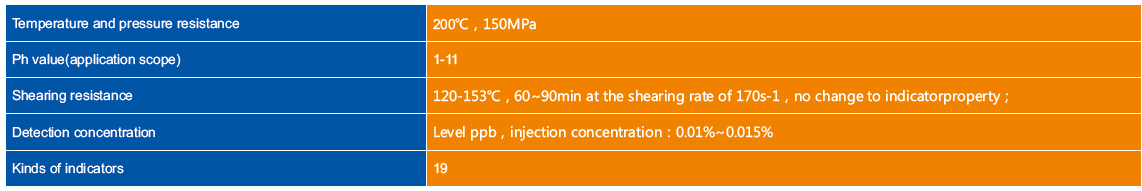

Specifications

Application Cases

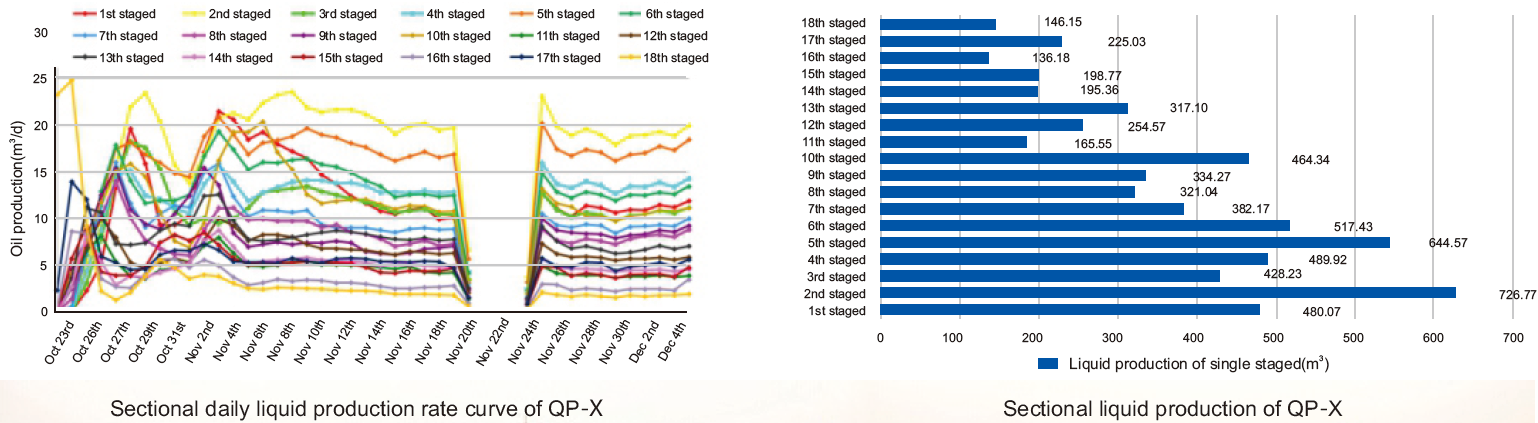

Our tracking and evaluation service of production capacity withindicatorwas successfully used for 493 sections in 57wells in Daqing oil field, Jilin oil field and Changqing oil field. Thereinto the most sections evaluated for a single well is 19. The service was applied for18 sections of Well QP-X in Daqing oil field to evaluate the production rate, flowback rate, contribution rate and production fluid profile of each section in initial production period.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......