Technical Service of Deflection Fracturing

Introduction

According to fracture mechanics,the hydraulic fracture always starts at the location of the formation section with good physical property, low fracture pressure and low tensile strength, and one

major fracture will form. Deflection fracturing technique uses chemical temporary plugging agent to plug the formed fracture and then break down new fracture, which finally reaches the

result of multi section and fractures improving the individual well yield. Calculate the rock mechanical parameters and fracture pressure by use of logging data and then determine the number of secondary fractures in the target section combined with crack interaction theory. Optimize several fractures with idealcracking points and determine volume of temporary plugging agent for multi fractures to conduct the plugging operation.

In traditional staged multiple fracturing of horizontal wells, only sections with high permeability and low fracture pressure can be put to use mostly. Its difficult to fracture the low permeability sections. And even if such sections are fractured, the sand pack result is poor, which leads to a poor improvement for production.

However, sectional multi-fracture volume fracture technique can be used to effectively use sections with different permeability level and finally improve the individual well yield and the final recovery efficiency. In additional after the major fracture is filled with sand, diverting agent can be used to plug the major fracture and make new diverting fractures, which finally forms complicated fracture net and improve the production.

Advantages

• Deflection fracturing technique can complete the volume fracture with conventional fracturing scale, forming complicated intensive fracture net to cut the sand and improving the first-time producing extentmaximally;

• Multi-fracture volume fracturing technique in single section greatly increase the possibility to connect the fault and fractures by manually controlling the hydraulic fracture trend;

• Deflection fracturing technique greatly decreases the tools put to use and the comprehensive construction cost without changing the original fluid system;

• Deflection fracturing technique greatly increases the exploitation economic benefit through increasing the final cumulative production by 30-40% compared with the conventional staged fracturing technique;

• Good bearing strength, degradation rate and resistance to elevated temperatures provide conclusiveguarantee for a successful multi-fracture volume fracturing in single section.

Application Cases

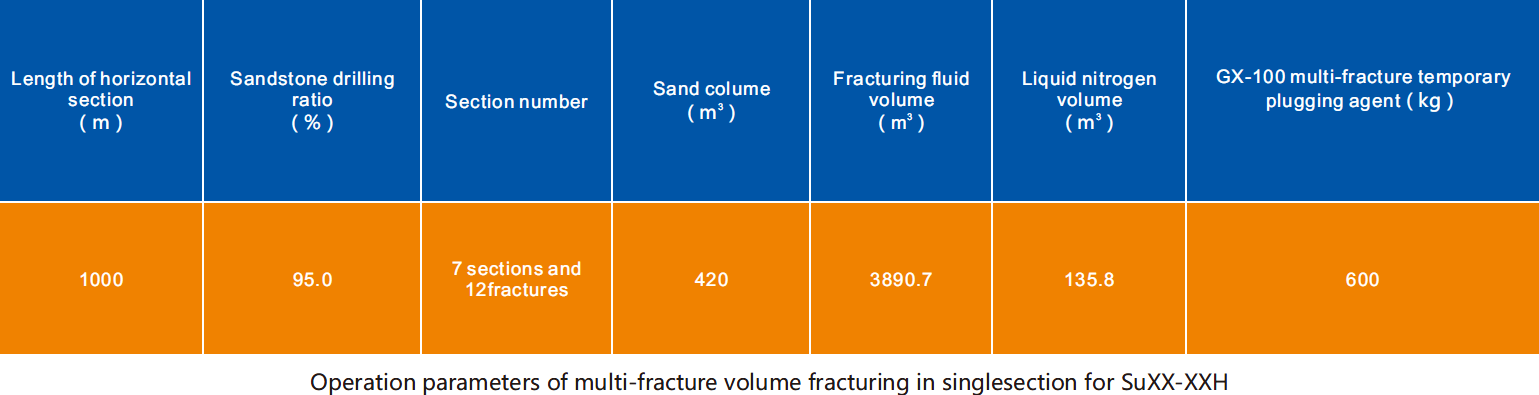

By the end of 2013, multi-fracture volume fracturing in single section has been applied for field tests and applications of more than60 wells, getting significant production enhancement and stabilizing effect. Thereintothis technique are applied for field tests and applications of 50 wells in Sulige gas field (He 8, Shan 1 and Xiagu) , field tests of 10 wells in Daniudi field(Shan 1, Tai 2 and Xiagu), field tests of 4 wells in Southwest oil and gas field, and field tests of 1 well in Zhejiang competent oil field. The field tests of multi-fracture volume fracturingin single section has been conducted for 18 horizontal wells in Block Su XX.

Thereinto fracturing tests were conducted for 2 wells and the ground multi-componentmicroseismreal-time monitoring technique was used to monitor the fractures, which finally verify the validity of the technique.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......