Turbodrill

Scope of Application

• The turbodrill has soft features such as high speed, large torque. It is free from lateral vibration and its rate of penetration is quite high. The all-metal turbodrill is resistant to high temperature. It applies to operations in deep shafts and high temperature conditions. Such turbodrills are insensitive to oil-based drilling fluid; therefore, it also applies to high-density drilling fluid.

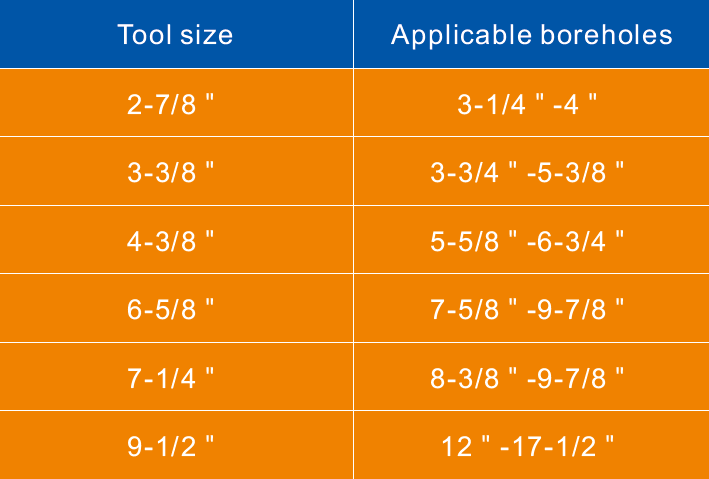

• Size of boreholes: 3 ¼” to 17 ½”;

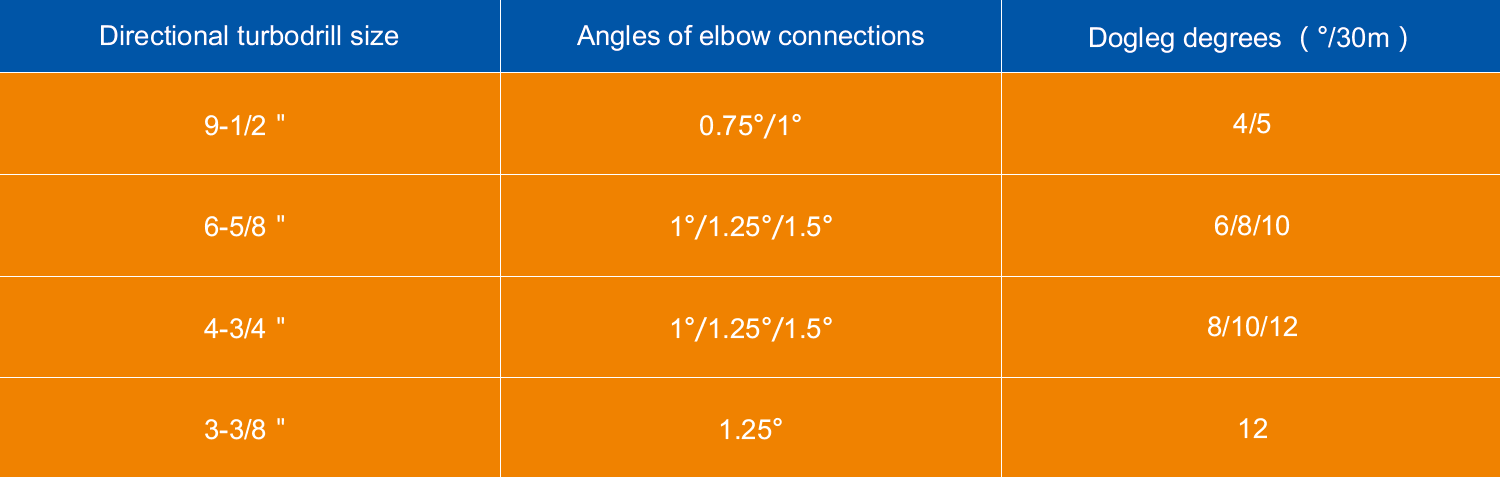

• Adjustable bends, used for vertical wells and directional drilling;

• Superhigh temperature drilling, the maximum temperature reaches 320℃;

• Improves the drilling speed in stratums with high abrasiveness and poor drillability;

• Improves single drilling footages.

Technical principle

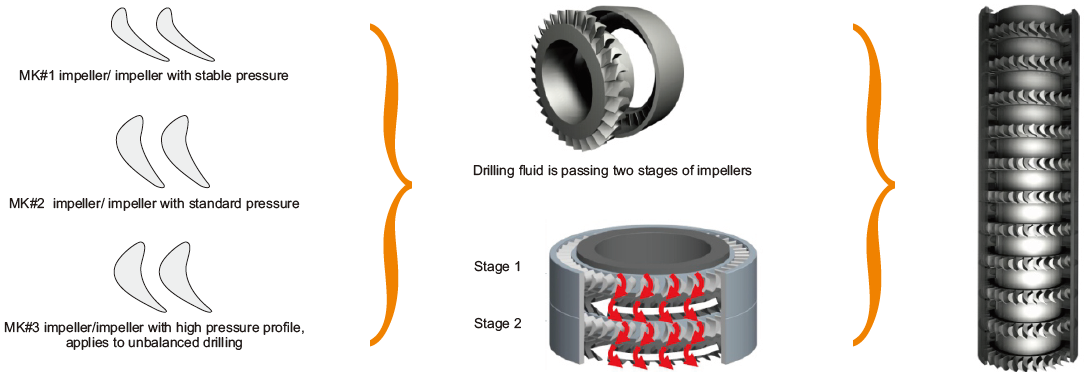

The main part of the turbodrill is a turbine. Each stage of turbine is composed of one stator and one rotor. Because the power output of one stage of turbine is too small, such a turbodrill is usually combined by hundreds of turbines with the same structures

in series. In order to sustain large axial load, a thrust bearing is equipped inside the turbodrill. In addition, there are two intermediate bearings equipped at one third and two thirds of the main shaft respectively to correctly support the main shaft. The basic parameters representing the performance features of the turbodrill include torque, revolving speed, output power, flow, pressure drop and efficiency. In particular, torque, revolving speed and output power are the most parameters representing the power capacity and features of the turbodrill. Flow, pressure drop and input power are important conditions for ensuring its operation with high proficiency and rapid drilling with proper use of such turbodrills.

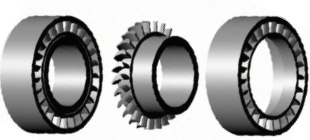

Bearing

First part of turbine power Second part of turbine power

Technical features

• It has outstanding stability for it has a record of continuous operation for 850 hours under the shaft;

• The power system does not rely on rubber materials any longer. Therefore, such turbodrills can be used for superhigh temperature drilling. The maximum temperature resistance = 320°C (static temperature);

• Perfect axial balance; vibration is reduced, which makes smooth borehole quality;

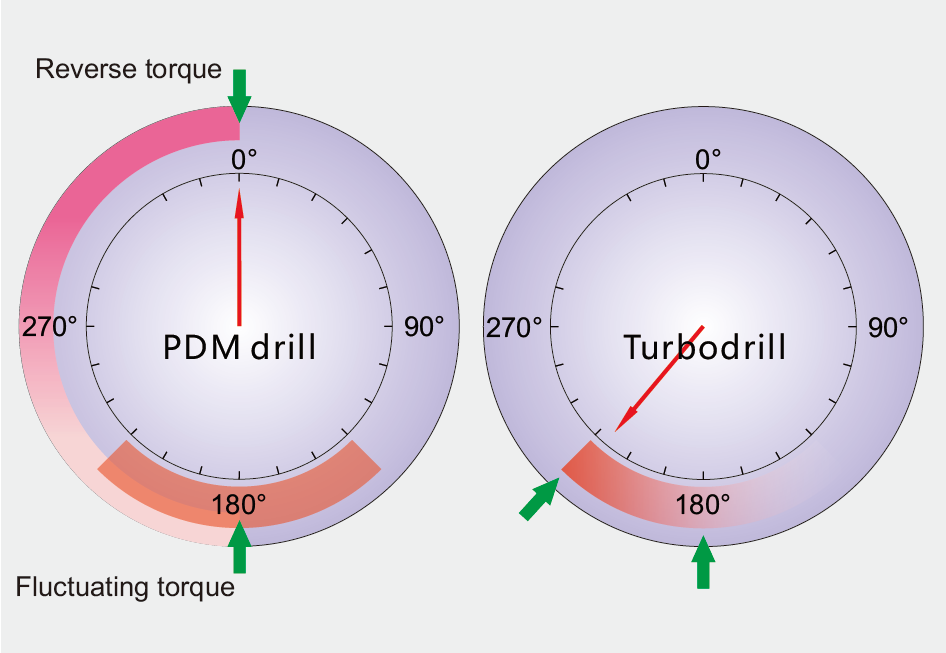

• Stable tool face control can lower damages of the drilling tool due to vibration;

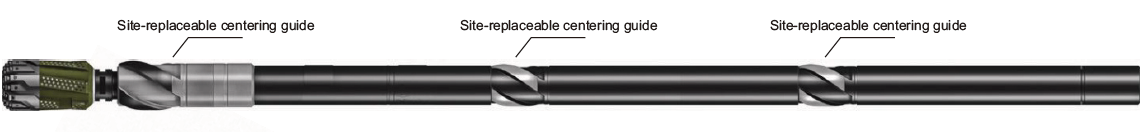

• The drill floor has adjustable bends and replaceable centering guides.

• It applies to a wide range of boreholes with dimensions from 3 ¼” to 17 ½”.

• NPT and comprehensive drilling cost are reduced by the improvement of rate of penetration and single drilling footages.

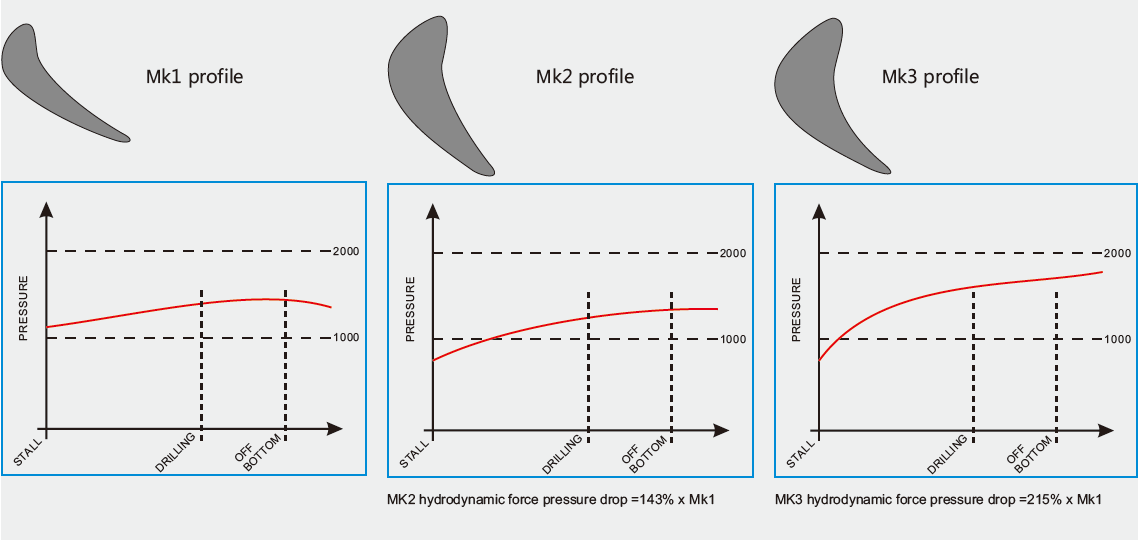

Stator and rotor impeller

Mub motor Turbodrill

Tool face when leaving shaft bottom

Technical Indicators

Service capacity and track records

• Yuanba Area in Sichuan

Challenge: The main form of Sinopecs project from Yuanba artesian well to Xujiahe Fm is dense sand mudstones with gravels. The stratum cement is quite compact and the compressive strength is high (21,000~24,000 psi). The rate of penetration for regular roller bits and pendulum assembly is quite low (1m/hour) and the single drilling footage is not deep (average 50m or so).

Solution: Smith 9 ½” turbodrill and Kinetic impregnated diamond bits are combined for operation.

Results: the single drilling footage of 12.25 tool reach 529m and the average rate of penetration reach 1.86m/hour respectively; the length of single drilling under well operation was 21 days, which save about 20 days by comparing with the same footage

in neighboring wells.

• Summary on application of turbodrills and impregnated bits in China

Daqing Oil Field, Jilin Oil Field: Denglouku Fm sand mudstone interbedding, Yingcheng Fm deep stratum volcanic, glutenite, Liaohe Oilfield: buried hill migmatitic granites;

North China, Dagang Oilfield: tough mudstone and Wumishan Fm dense dolomites, high temperature well, 200 celsius degrees;

Shenli Oil Field: dense sandstone reservoir acceleration;

Changqing Oilfield: Shanxi Fm, Taiyuan Fm quartz sandstones;

Sinopec South Company, CNPC Southwest Oil Gas Company: Xujiahe Fm dense sandstones and dense shales in other stratums;

Tarim Oilfield, Xinjiang Oil Field: high temperature and high pressure, increase of drilling speed.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......