Pumpdown perforating- bridge plug combined operation technology

Introduction to the technology

Mainly used for shale gas development.Providing more favorable environment for fracturing

The process is complicated, integrating perforating,

bridge plug setting, hydraulic propelling and other technologies

Equipments and downhole tools

Logging truck

Benz logging truck: Five units

Power: 235kw/320hp Cable lifting speed: 120m/h——11000m/h

Wellhead blowout control equipment

Imported blowout control equipment: Three

sets of Hunting 105Mpa and five sets of Elmar 70Mpa

Quantity of equipment: Three sets of (Hunting

105Mpa)+ two BOPs+two QTSs; five sets of (Elmar 70Mpa)

Operation capacity: Can operate in ten

wells at the same period (including one-hold-two-type operation)

High-pressure well operation capacity: Can

operate in five high-pressure wells (over 95Mpa) at the same period (including one-hold-two-type

operation and a single well operation).

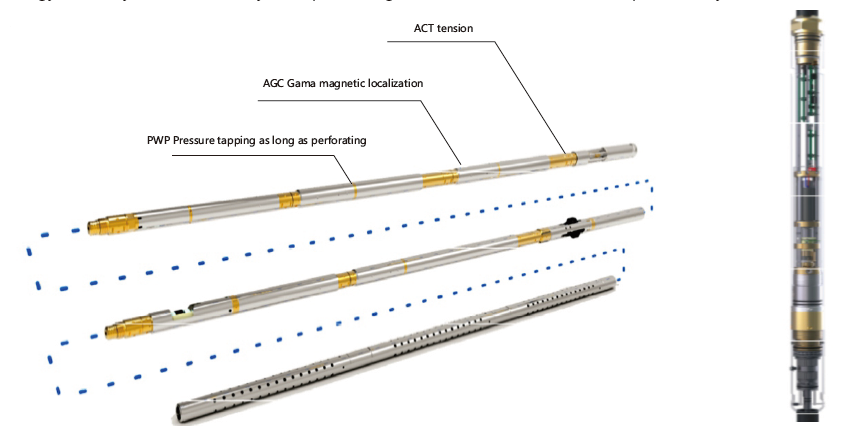

Downhole tool series

DYNA multi-stage ignition system: Ten sets

Type: Electronic multi-stage optional launching

Tolerable temperature: 175°C

Tolerable pressure: 140Mpa

Perforating gun: 89mm&20 perforations/m

Bridge plug and setting tools

Fast-drilling bridge plug

Tolerable temperature: 121-177°C

Tolerable pressure: 56-105Mpa

Setting tool: Ten sets of Baker 20#

New technology

•Unified-perforation type perforating technology

•After perforated by DPEX perforating bullet, the trajectory will be cleaned automatically. Oriented perforating technology

•Pressure tapping as long as perforating technology

Unified-perforation type perforating bullet

Ordinary perforating bullet

Principle of unified-perforation type perforating

bullet

Perforating bullet

The explosive for all the perforating

bullets are the same: RDX\HMX\PYX

Different perforating bullets only differ

in the design of liner and cartridge

Unified-perforation type perforating bullet

•The design of liner angle differs from that

of ordinary perforating bullet; it can control the explosive within energy

collection and scattering

•After ignition, the set flow will be in the

shape of column and launched toward the ground

•If the set flow is launched in the shape of

column, different-phase casing and formation bore size will be consistent

without centering guide

•Lots of tests have been implemented to find

proper angle for liner

Ordinary perforating bullet

•The design of liner makes the explosive

more energy-gathered

•After ignition, the set flow will be in the

shape of cone and launched toward the ground

DPEX self-cleaning perforating bullet

Principle of self-cleaning perforating

bullet

Perforating bullet

•The explosive for all the perforating

bullets are the same: RDX\HMX\PYX

•Different perforating bullets only differ

in the design of liner and cartridge

Self-cleaning perforating bullet

•Reactive metal material is adopted for the

liner

•After perforating, exothermic reaction of reactive

metal material will occur in the trajectory along with the jet flow

•After exothermic reaction, ultrahigh

pressure will be generated in the trajectory, so the perforating fragments will

flow back to the shaft along with the fluid

•The ultrahigh pressure in the trajectory

will last for a while, so the fragments in the trajectory will be cleaned up

and the trajectory will be clean

Ordinary perforating bullet

•Inert metal material is adopted for the

liner

•After perforating, the liner will melt or

be blasted into fragments

Oriented perforating

Oriented perforating technology: can

realize oriented perforating of different positions while descending the well

for once. Previously, to realize the oriented perforating of a position, the

operator shall descend the well for three times: for the first time, he shall

set the bridge plug with locationing slot; for the second time, he shall lower

the gyroscope to measure the relative azimuth of the locationing slot; for the

third time, he shall put the perforating gun into the locationing slot can

start perforating. Now, to realize oriented perforating of different positions,

we just need to descend the well for only once.

Pressure tapping as

long as perforating

Pressure tapping as long as perforating(PWP)

technology: A. Record the rapid pressure response; B. Detect the peak pressure

and under-balance pressure while perforating; C. Determine the fracture

pressure and cleaning pressure; D. Evaluate the oil well energy efficiency and

the necessity of re-perforating; E. Calculate the near-borehole permeability

within 5-30 s after perforating gun launching.

Information about technician

Beijing YilongHengye Oil Technical Engineering

Co., Ltd. establishes perforating service center in charge of the company’s pumpdown

perforating- bridge plug combined operation business; it has twenty-nine

technicians and five high-pressure pumpdown perforating teams, in which, there

are three senior engineers, four engineers, three senior technicians and

nineteen operators.(December, 2014)

Field service of pumpdown perforating-

bridge plug combined operation technology

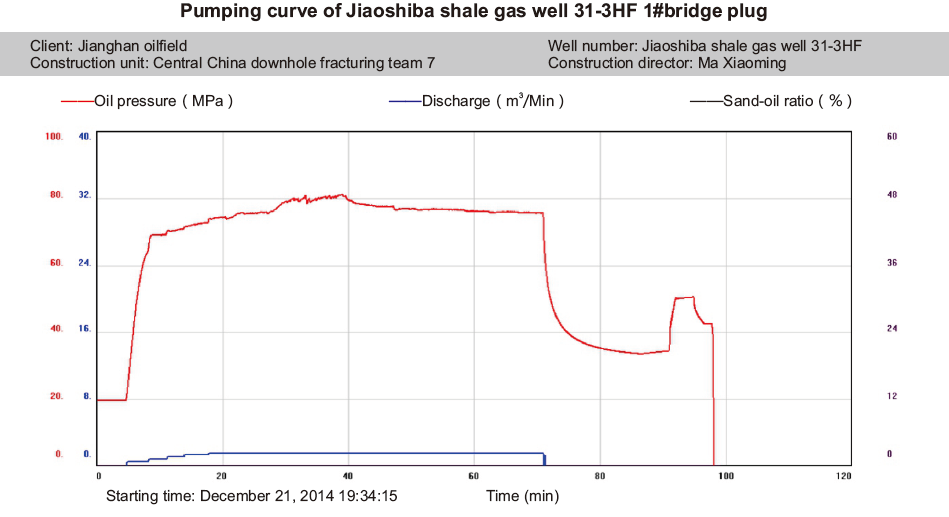

Construction effect

The max. pumping pressure of the first

section of JY31-3HF well is 82Mpa; and there is no leakage in the Hunting

105Mpa wellhead blowout control equipment.

Performance

Since 2012, totally completed over 618 wells at about 6700 level in Jiaoshi area, North China Bureau area, extended area, East China Bureau, Northeast Bureau and Puguang area.The companys outstanding performance in perforating has been well recognized and praised by party A, it even expresses its thanks by visiting our company.

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......

北京一龙恒业石油工程技术有限公司成立于2005年,总部位于北京望京科技园区,是北......